Electrical Part¶

Electrical Box¶

Note

There is another Electrical Box which is about 130$ cheaper but 15-20% slower and 40% less powerful (instead of 29 lbs thrust 17 lbs) The Box is 3D printed.

Driver : Cheap Driver Aliexpress

Power 24V, 6A : Power 24V 6A Aliexpress

Listing Parts¶

Cable Silicone 3 Cores¶

Length : 1x 2m

Type : 0.75mm^2

Note : I used silicone because it’s easy to fold.

Plug 110 / 220 V¶

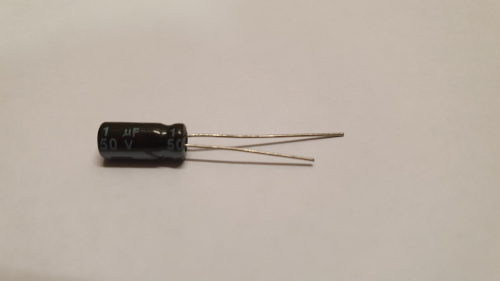

Capacitor Polarized 1uF¶

Quantity : 1x

Purpose : This reduce the noise while reading the speed on the remote-control

Square 10-12-9mm¶

Quantity : 2x

Material : aluminium

Purpose : Reinforcement of the fixaton (glue) of the Arduino Uno to the U Base

Countersunk Head Screw M3 x 8mm¶

Quantity : 4x

Material : Stainless Steel

Purpose : To fix Geckodrive on the U Base

Countersunk Head Screw M3 x 12mm¶

Quantity : 4x

Material : Stainless Steel

Purpose : To fix the Connector Socket 5 pins Female Insert on the U Right

Countersunk Head Screw M3 x 14mm¶

Quantity : 3x

Material : Stainless Steel

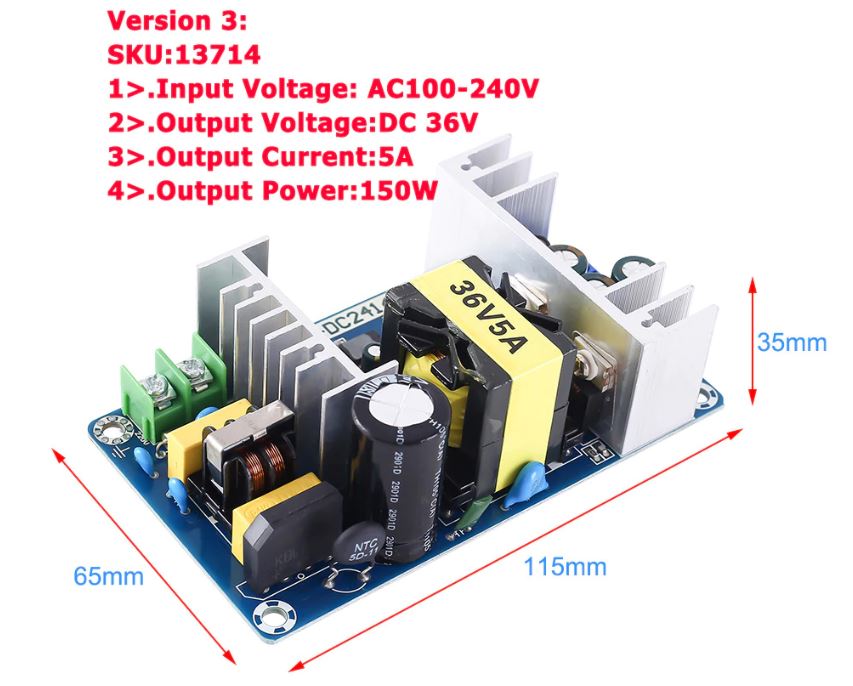

Purpose : To fix the Power 36V on the U Base

Countersunk Head Screw M3 x 16mm¶

Quantity : 1x

Material : Stainless Steel

Purpose : To fix the Power 36V also the Ground Terminal on the U Base

Glue Silicone¶

Quantity : 1x

Type : Polyflex 444

Purpose : To glue the Arduino Uno to the U Base using the Square 10-12-9mm to fix stronger

Operation Plan¶

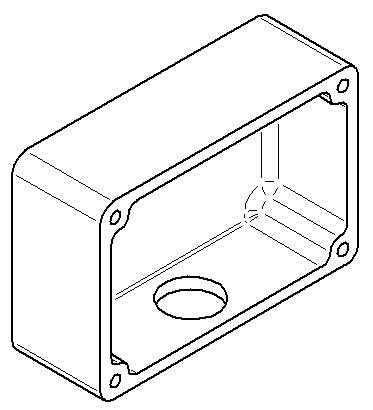

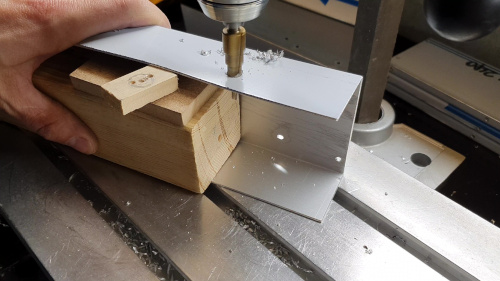

Make The Sheets Parts¶

Make the U Base, U Right and the U Left following this Video, see also the drawings below :

Drawings :

Material : aluminium

U Base¶

U Top¶

U Right¶

U Left¶

Make the Spacer 6-8-3mm¶

See the following video :

Drawing :

Quantity : 4x

Material : aluminium

Spacer 6-8-3mm¶

Make the Square 10-12-9mm¶

See the following video :

Drawing :

Quantity : 2x

Material : aluminium

Square 10-12-9mm¶

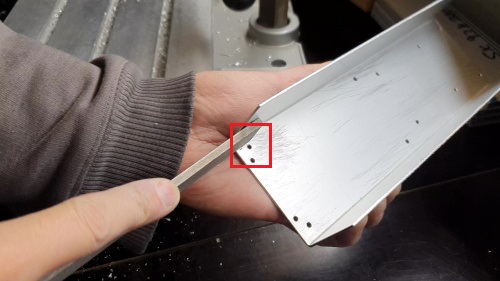

Scrape the surface on the U Base¶

File the bottom of the U Base (only the part where the red framed hole is) so that the grounding contact faces well. This operation is not necessary if you are using non anodized sheets.

Note

The anodized surfaces are not conductive.

See Video :

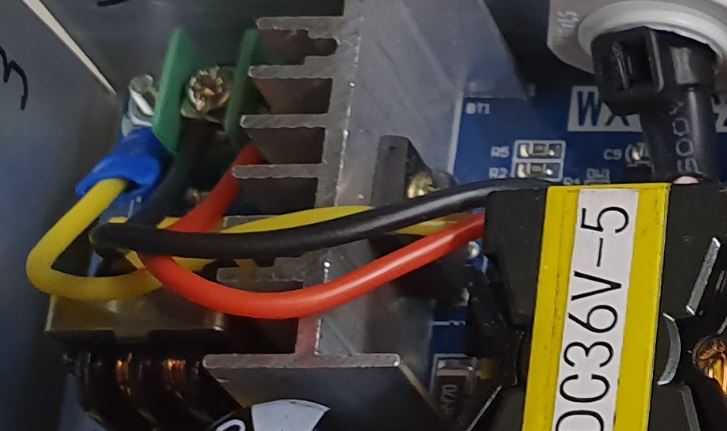

Control Power 36V¶

Control the voltage of the output of the Power 36V with a voltmeter. It should be 36V.

Adjust voltage Power 36/12V¶

Materials:

1 wire 0.5mm^2 red length = 120mm

1 wire 0.5mm^2 red length = 150mm

1 wire 0.5mm^2 black length = 140mm

1 wire 0.5mm^2 black length = 60mm

Sold the wire

Wire the Power 36/12V

Connect the Power 36/12V IN to the Power 36V OUT

Connect the voltmeter to Power 36/12V OUT

Adjust the voltage

With a Screwdriver 0, adjust the voltage to 12V

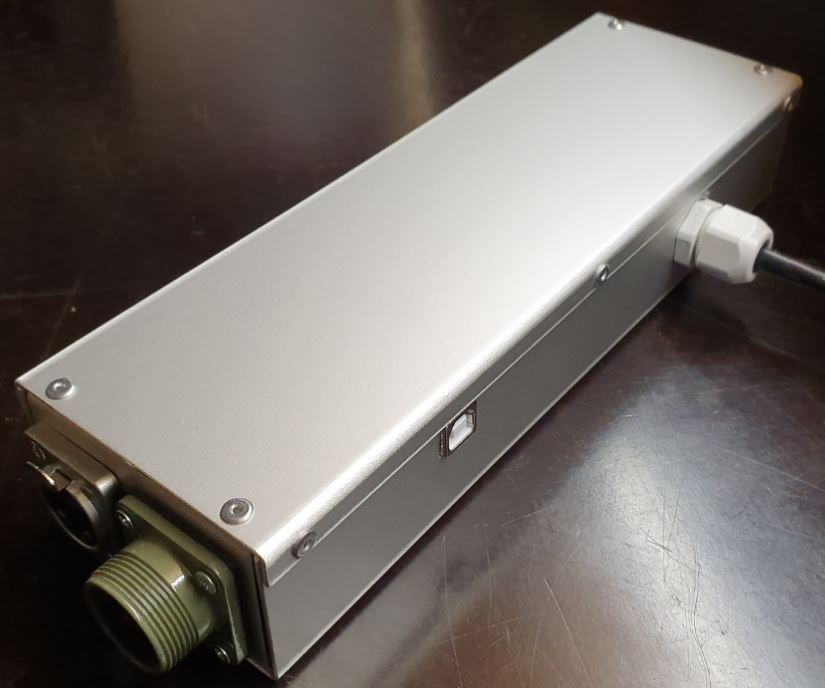

Fix the Power Cable to the Electrical Box¶

See Video :

Strip the Cable Silicone 3 Cores at 10cm

Fix the Cable Gland to the U Base

Tighten Cable Gland

Tighten the Cable Ties and cut it with a Cutting Pliers

Tighten the Ground Terminal M3 on the ground wire (yellow)

Tighten the Phase and Neutre to Power 36V “IN”

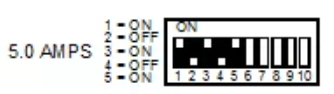

Set Geckodrive current limit¶

Screw the Power 36V and Geckodrive on the U Base¶

Note

Use Threadlocker Glue.

For Power 36V :

- Fix three corners of the Power 36V by using :

3x Spacer 6-8-3mm

3x Countersunk Head Screw M3 x 14mm

3x Washer M3

3x Nuts M3

- Fix the last cornerThe ground to the U Base by using :

1x Countersunk Head Screw M3 x 16mm

1x Washer M3

1x Nuts M3

1x Ground Terminal M3 (the ground on the Cable Silicone 3 Cores

For Geckodrive use :

4x Head Screw M3 x 8mm

4x Washer M3

4x Nuts M3

Glue the Power 36/12V and Arduino Uno¶

Glue the Arduino Uno at the U Base with Glue Silicone and Square 10-12-9mm and the Power 36/12V.

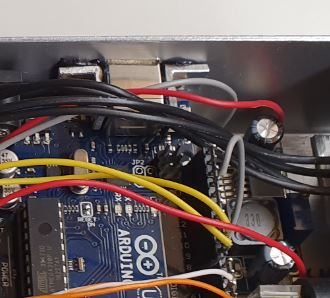

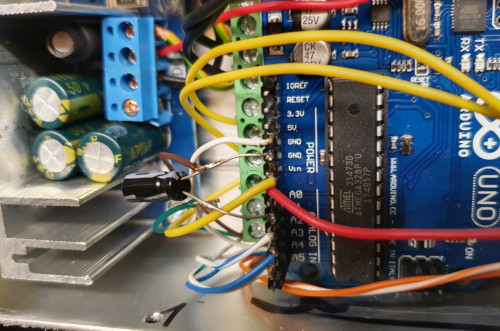

Wiring¶

See video :

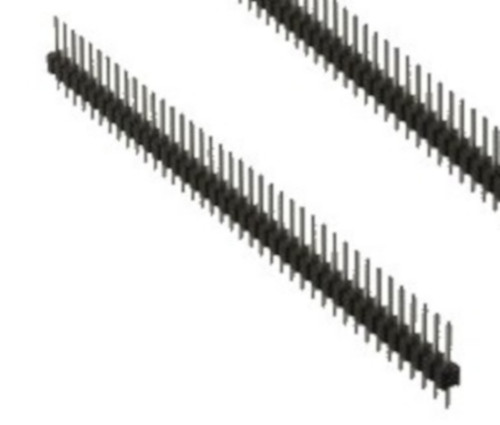

Sold the wires to the Male PCB PIN Header (15, 10, 8 pins), except the POWER 36/12V OUT+

Use two clamps this help to sold the Male PCB PIN Header

Male PCB PIN Header 15 pins¶

Male PCB PIN Header 10 and 8 pins¶

GECKODRIVE |

ARDUINO |

Cable Length |

|---|---|---|

8 (DIR) |

PIN 8 |

11cm |

9 (STEP) |

PIN 9 |

11cm |

10 (COMMON) |

GND |

7cm |

POWER 36/12V |

ARDUINO |

Cable Length |

|---|---|---|

OUT- |

GND |

6cm |

OUT+ |

VIN |

12cm |

ARDUINO |

RJ45 cable (inside Box) |

Cable Length |

|---|---|---|

A0 |

6 sold capacitor + |

12cm |

A1 |

5 |

“ |

A2 |

4 |

“ |

A3 |

3 |

“ |

~3 |

2 |

15cm |

~5 |

1 |

“ |

GND |

8 sold capacitor - |

12cm |

+5V |

7 |

“ |

Sold the Capacitor between A0 and GND (8) see folowing picture

Connect :

Power 36V |

GECKODRIVE |

Cable Length |

|---|---|---|

-DC |

1 (POWER GND) |

6cm |

D+ |

2 (18 TO 80 VDC) |

“ |

Power 36V |

POWER 36/12V |

Cable Length |

|---|---|---|

-DC |

IN- |

14cm |

DC+ |

IN+ |

15cm |

GECKODRIVE |

Female Connector (MOTOR) |

Cable Length |

|---|---|---|

3 (WINDING A) |

A |

15cm |

4 (WINDING not A) |

B |

“ |

5 (WINDING B) |

C |

“ |

6 (WINDING not B) |

D |

“ |

Upload the programm to Arduino Uno and final control¶

Plug the PC using an USB cable to the Electrical-Box

Upload the programm (soon available)

Control if every thing is ok (the *Machine, Remote Control, Stepper Motor and the Rod should be done). Do all these steps showed in that video for the test :

Cover with U Top and Rivet

Remote Control¶

Listing Parts¶

Operation Plan¶

See the video :

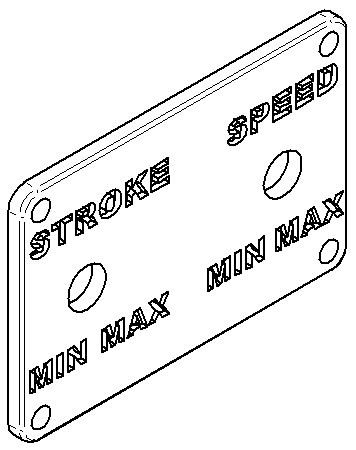

Make the Box¶

Print it in PLA. Infill = 50% File : soon available…

Make the Cover¶

Print it in PLA. Infill = 50% File : soon available…

Prepare the Epoxy with black pigment, red pigment and green pigment

Fill with pigmented Epoxy the inscriptions on the Cover

Cure the Epoxy then sand it very thin (60, 240, 400)

Place the Potentiometer (2x) and and tighten them

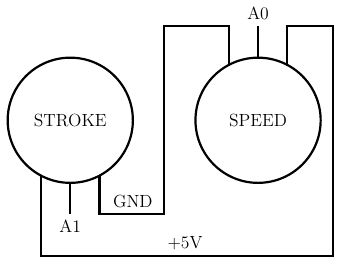

Wiring the Remote Control¶

Remote-Control |

RJ45 cable |

Wire Color |

|---|---|---|

A0 |

6 |

G |

A1 |

5 |

b |

GND |

8 |

BR |

+5V |

7 |

br |

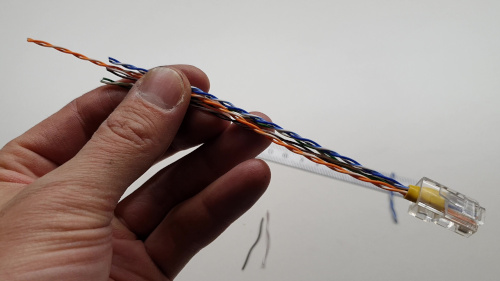

Strip the RJ45 Cable at 7cm

Cut the unused wire

Use the cutted unused wire to make the bridge between GRD and +5V inside the Remote Control

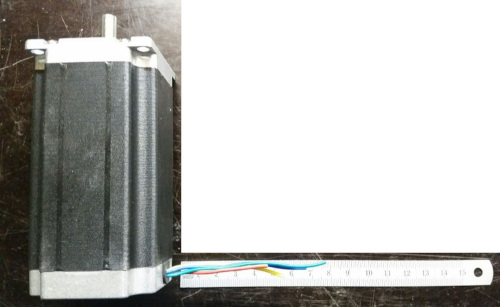

Motor¶

This section shows how to fix the Cable Silicone 4 Cores to the Connector Plug 5 pins Male Insert and the Motor

Listing Parts¶

Screw Hex Head Allen M5 x 40¶

If the Motor isn’t fixed yet on the Machine, then 1x Screw is needed.

Quantity : 1x

Size : M5 x 40

Type : Stainless Allen Bolt Socket Cap Screw Hex Head Allen Key DIN912

Connect and fix the Cable Silicone 4 Cores to the Motor¶

Operation Plan¶

See the video :

Make the Tube Cable Holder

Tube Cable Holder (material aluminium anodized)¶

Unpacking and motor control. Plug the 4 wires on an Electrical Box and make it turn. This is important before making the following steps.

There are two kinds of motor a 3A and a 4.2A each motor has their own colors of wire. Depend on the Amps of the motor you use, cut the wire as follow :

Motor 3A :

red wire 47mm

yellow 57mm

blue 67mm

green 77mm

3A motor with wires cutted¶

Motor 4.2A :

red 47mm

green 57mm

black 67mm

blue 77mm

Stripping, twisting, tinning the motor wires to 5mm

Cut the Heat Shrink Tube to 37mm length and tighten it with industrial foehn. The red wire should protrude about 5mm..

Cut the Cable Silicone 4 Cores at 2.2m

Strip the Cable Silicone 4 Cores to 45mm.

Cut the wires on the Cable Silicone 4 Cores as follow: - red 40mm - yellow 30mm - black 20mm - green 10mm

Strip, twist, tin-plate the cable wires to 5mm.

Cut 4x Heat Shrink Tube at 13mm

Put 13mm Heat Shrink Tube + Tube Cable Holder (pay attention to direction the chamfer 1x45) and solden

Degrease Tube Cable Holder, Cable Silicone 4 Cores and Motor with acetone

Warning

If the Motor isn’t fixed on the machine yet, then don’t forget to put the screw in the motor hole (see picture below)

Inject the Glue Silicone through the 4mm hole diam. until it comes out of both sides of the Tube Cable Holder; take the surplus and apply it to the Motor on the groove where the Screw Hex Head Allen M5 x 40 has been placed; turn the Tube Cable Holder so that the injection hole is against the Motor and is not visible; put a Cable Ties on the Cable Silicone 4 Cores , put the Tube Cable Holder on with the clamp see following picture

if necessary, inject at the end of the Tube Cable Holder where the chamfer is located and put some Glue Silicone on the Motor if you see the wires that protrude a little beyond the Heat Shrink Tube

Allow to harden; clean and remove the beads on Tube Cable Holder.